Inside the Heart of Fire Pumps: Understanding Hydraulic Efficiency and Energy Recovery

Introduction

In every modern fire fighting system, the fire pump acts as the beating heart driving water with force, reliability, and precision when seconds truly matter. Whether protecting high-rise buildings, industrial plants, or oil refineries, the efficiency of that pump determines not just how quickly water reaches the fire, but also how much energy the system consumes in the process.

At DFS, the exclusive agent of NMFIRE in Saudi Arabia, efficiency and reliability are not just design features they are commitments. As fire protection demands evolve and energy efficiency becomes an operational necessity, understanding the hydraulic efficiency and energy recovery mechanisms inside fire pumps has never been more important.

This article takes you inside the heart of fire pumps exploring how modern impeller designs, Computational Fluid Dynamics (CFD) simulations, and hydraulic optimization are transforming performance while minimizing energy loss.

1. What Is Hydraulic Efficiency in a Fire Pump?

Hydraulic efficiency is a measure of how effectively a fire pump converts mechanical energy (from a diesel engine or electric motor) into kinetic energy (water flow and pressure). In simple terms, it’s the ratio between the pump’s useful output and the total input power.

A perfectly efficient pump would transfer all the input power into moving water but in real-world systems, energy is inevitably lost due to friction, turbulence, and mechanical resistance. The goal of advanced design and simulation is to minimize these losses.

For fire fighting systems, where pumps often operate under demanding conditions and must deliver consistent performance during emergencies, optimizing hydraulic efficiency ensures:

- Reduced energy consumption during testing and operation.

- Lower wear on components, extending pump life.

- Stable pressure and flow across varying system conditions.

2. The Science of Energy Loss in Fire Pumps

Even the most advanced fire pumps experience energy losses through three main mechanisms:

- Hydraulic Losses

These occur due to fluid friction and turbulence within the pump casing, impeller passages, and suction/discharge nozzles. Poorly shaped impeller blades or rough surfaces increase resistance, leading to wasted energy.

- Mechanical Losses

Mechanical losses arise from bearing friction, seal drag, and shaft misalignment. While minor compared to hydraulic losses, they still affect the overall efficiency of the fire pump.

- Volumetric Losses

These losses are caused by internal leakage of fluid through clearances between impeller and casing or wear rings. Over time, as clearances widen due to wear, leakage increases reducing volumetric efficiency.

Each of these losses contributes to the difference between theoretical efficiency and actual field performance. High-quality fire pumps from NMFIRE, engineered with precision manufacturing and advanced CFD validation, are designed to reduce these losses to an absolute minimum.

3. The Role of Impeller Design in Hydraulic Efficiency

The impeller is the core hydraulic component of any centrifugal fire pump it is where energy transformation begins. The design of the impeller blades, hub, and shroud determines how efficiently the pump converts mechanical power into water motion.

Key Factors in Impeller Efficiency:

- Blade Geometry

- The curvature and thickness of blades directly affect the velocity distribution and turbulence level.

- Optimized curvature ensures smoother water flow, reducing shock losses at entry and exit.

- Number of Vanes

- More vanes can provide smoother flow but increase friction surface.

- Too few vanes cause higher hydraulic losses due to excessive slip.

- Designers must find the ideal balance typically between 5 and 7 vanes for fire pumps.

- Eye Diameter and Outlet Width

- Larger impeller eyes reduce inlet velocity and risk of cavitation.

- Correct outlet width ensures balanced velocity distribution, enhancing both head and efficiency.

- Material and Surface Finish

- NMFIRE impellers are manufactured using precision casting and advanced surface treatment to minimize roughness, thereby reducing hydraulic drag.

By refining these design parameters using CFD simulations, engineers can predict and eliminate energy loss areas long before physical prototyping, achieving superior hydraulic performance.

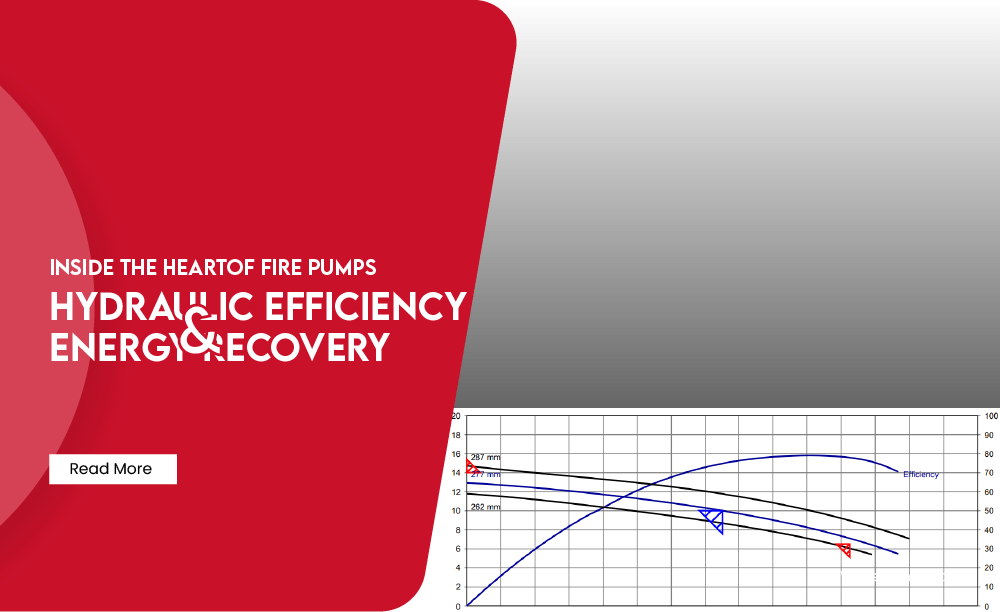

4. Computational Fluid Dynamics (CFD): The Game-Changer

What Is CFD?

CFD is a simulation technology that models the flow of fluids through 3D geometries using advanced numerical analysis. It enables engineers to visualize water movement, velocity vectors, pressure gradients, and turbulence within a pump.

How CFD Enhances Fire Pump Design

- Visualizing Flow Patterns – Engineers can identify flow separation zones, vortex formation, and recirculation areas that lead to efficiency loss.

- Optimizing Blade Angles – CFD allows fine-tuning of blade curvature and thickness to ensure the smoothest flow.

- Cavitation Prediction – It helps predict NPSH (Net Positive Suction Head) requirements and avoid cavitation-related damage.

- Energy Recovery Zones – Designers can study how diffuser vanes and volute design recover kinetic energy as pressure, improving overall performance.

At NMFIRE, CFD analysis is integrated into every stage of product development from impeller optimization to volute casing refinement ensuring that every pump meets global performance standards like UL, FM, and NFPA 20.

5. Energy Recovery in Fire Pump Design

The Concept

After water leaves the impeller, it still contains high kinetic energy. The volute casing and diffuser are responsible for recovering this kinetic energy and converting it into useful pressure energy.

Volute Design

A volute is a spiral casing surrounding the impeller that gradually expands in cross-section. This expansion reduces water velocity while increasing pressure a process known as diffusion.

- A well-designed volute ensures uniform pressure distribution around the impeller periphery.

- Poor volute geometry can cause hydraulic imbalance, vibrations, and reduced efficiency.

Diffuser Vanes

Some high-efficiency fire pumps use diffuser vanes to further slow down the flow and recover energy. These stationary blades guide the water smoothly toward the outlet, reducing turbulence and improving pressure recovery.

By combining optimized impeller design with advanced volute and diffuser geometry, modern fire pumps achieve up to 85% or higher hydraulic efficiency, even under demanding operating conditions.

6. The Relationship Between Efficiency and Reliability

Higher hydraulic efficiency doesn’t just mean lower energy costs it directly impacts pump longevity and reliability. When internal flow is optimized:

- Less vibration and wear occur on bearings and seals.

- Cavitation risk is minimized, protecting the impeller and casing.

- Temperature rise within the pump is reduced, ensuring consistent performance.

For mission-critical applications such as data centers, airports, oil terminals, and skyscrapers the reliability of a fire pump is non-negotiable. NMFIRE’s engineering approach emphasizes both performance efficiency and mechanical durability, ensuring dependable fire protection when it matters most.

7. Testing and Validation: From Simulation to Reality

CFD analysis provides powerful insights, but real-world validation is essential. NMFIRE conducts comprehensive testing under UL and FM certification standards, verifying every aspect of hydraulic and mechanical performance.

Key Test Parameters:

- Flow rate and total dynamic head

- Hydraulic efficiency curve

- NPSH (Net Positive Suction Head) performance

- Vibration and noise levels

- Mechanical integrity and bearing temperature

These tests confirm that the theoretical efficiencies achieved through design are fully realized in practice ensuring consistent field performance for every installed fire fighting system.

8. The Impact of Efficiency on Sustainability and Cost

While the primary purpose of a fire pump is emergency operation, energy efficiency still matters in day-to-day use:

- Routine Testing: Most facilities run their fire pumps weekly or monthly to comply with NFPA 25 testing standards. Efficient pumps consume less energy during these runs, saving operational costs.

- Reduced Heat and Noise: Higher efficiency translates to smoother operation, reducing heat generation and noise emissions.

- Lower Carbon Footprint: Optimized hydraulic designs contribute to sustainability goals — a growing priority in GCC markets.

For facility owners and engineers in Saudi Arabia and across the GCC, choosing a high-efficiency, UL/FM-certified NMFIRE pump through DFS ensures compliance, performance, and sustainability.

9. The Future of Hydraulic Optimization: AI and Digital Twins

The next leap in pump design is already underway. Digital twin technology a virtual replica of a physical pump allows continuous monitoring and predictive analysis. When integrated with AI-driven CFD, manufacturers can:

- Simulate performance over the pump’s lifetime.

- Predict maintenance needs before failures occur.

- Automatically adjust control parameters for optimal efficiency.

This fusion of digital technology and hydraulic engineering represents the future of smart fire fighting systems, combining real-time insight with decades of mechanical expertise.

DFS supports clients across the GCC with technical consultation, design support, and after-sales service, ensuring that every fire fighting system operates at its best when needed most.

Conclusion

The heart of a fire pump beats strongest when efficiency meets reliability. By understanding hydraulic performance and energy recovery, engineers and operators can ensure their fire fighting systems deliver the highest possible protection with minimal energy loss.

Through innovations in impeller design, CFD simulation, and precise engineering, NMFIRE and DFS continue to redefine what’s possible in fire pump performance delivering pumps that are not only powerful and reliable but also efficient, sustainable, and future-ready.