Inside the Engineering of NMFIRE Vertical Turbine Fire Pumps

Introduction

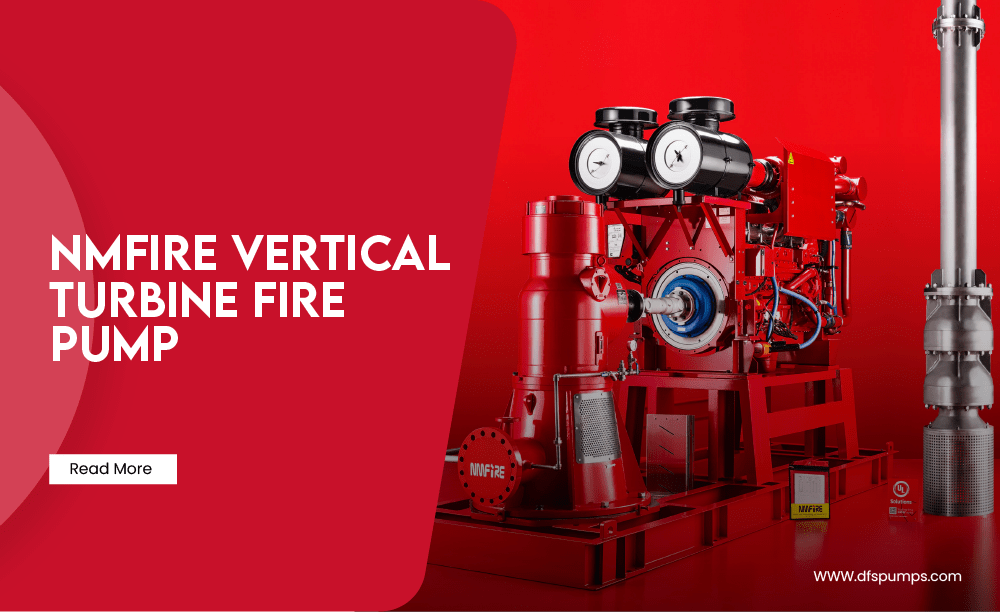

In the world of fire protection, precision and reliability define performance. Fire pumps are the beating heart of every fire fighting system, responsible for maintaining consistent water flow and pressure when emergencies strike. Among the various pump technologies available today, vertical turbine fire pumps stand out for their superior efficiency, durability, and versatility particularly in applications involving deep wells, tanks, or reservoirs.

At the forefront of this technology is NMFIRE, a global leader in UL and FM-certified fire pump solutions. Represented exclusively in Saudi Arabia by DFS, NMFIRE has redefined vertical turbine fire pump design with its unmatched engineering precision and commitment to NFPA 20 (2019 Edition) standards.

This article takes you inside the engineering of NMFIRE’s vertical turbine fire pumps exploring each major component, the innovations behind them, and how these design features combine to deliver reliable, efficient, and compliant performance in critical fire protection systems.

The NMFIRE Engineering Philosophy

Every NMFIRE fire pump is engineered around three core principles: efficiency, durability, and compliance. From hydraulic optimization to vibration control, each element of design follows rigorous testing and quality control to meet UL 448 and FM 1312 requirements.

According to NFPA 20 (2019 Edition), all fire pumps must be designed to ensure dependable operation at rated speed and flow under all specified conditions. NMFIRE not only meets these criteria it exceeds them by applying advanced design methods, precision casting, and data-driven hydraulic modeling to achieve peak performance with lower brake horsepower (BHP) requirements.

Hydraulic Design & BHP Efficiency

One of NMFIRE’s greatest engineering breakthroughs lies in its **new hydraulic system design**, specifically developed for vertical fire pump models. This design significantly **reduces pump BHP** and **minimizes submergence requirements**, directly translating to reduced energy consumption and overall system cost.

Lower BHP means the pump requires less input power to achieve the same hydraulic output. This ensures:

- Lower energy costs

- Smaller engine or motor requirements

- Reduced environmental impact

- Enhanced system efficiency

While **NFPA 20 (2019)** requires manufacturers to disclose the *maximum BHP*, many do not. NMFIRE proudly provides full transparency by highlighting its *maximum BHP values*, demonstrating performance integrity and compliance.

Precision-Cast Impellers: The Lost Wax Advantage

The impeller is the heart of every fire pump it converts mechanical energy into hydraulic energy. NMFIRE’s impellers are manufactured using the lost wax casting process, a method known for its superior precision and consistency.

This high-accuracy process ensures:

Perfect impeller balance

Smooth hydraulic surfaces

Predictable performance as designed

Reduced vibration and wear

The result is exceptional hydraulic efficiency, ensuring every pump delivers the flow and pressure it was engineered for without deviation.

Shafts, Couplings, and Alignment

Reliability in vertical turbine pumps depends on perfect alignment from top to bottom. That’s why NMFIRE’s pump shafts undergo ultrasonic testing to detect any internal flaws and guarantee material integrity.

Each shaft is machined with finely ground fitting surfaces to enhance straightness and concentricity, reducing vibration and mechanical stress during operation. Depending on shaft size, NMFIRE uses threaded or sleeve-type couplings to ensure precise connection and stable transmission of power.

This attention to detail not only enhances pump smoothness but also extends the overall lifespan of bearings, bushings, and other rotating components.

Material Options for Seawater and Corrosive Environments

NMFIRE recognizes that many vertical turbine pumps operate in **marine, coastal, or desalination environments**, where corrosion poses a serious challenge. For such installations, NMFIRE offers pumps constructed from Duplex Stainless Steel or Nickel-Aluminum Bronze (Ni-Al-Br) materials known for their high resistance to seawater corrosion and long service life.

These materials ensure:

– Extended pump longevity

– Lower maintenance requirements

– Reliable operation in high-salinity conditions

Every seawater pump is UL/FM certified, ensuring performance without compromise.

Gearbox & Torsional Coupling Technology

For diesel-driven vertical turbine fire pumps, NMFIRE’s FM-approved right-angle gearbox plays a critical role in power transmission. Designed with a dedicated water cooling system, it ensures stable operation and temperature control under continuous duty.

More importantly, NMFIRE is the only manufacturer that equips its pumps with a torsional coupling mounted on the engine side a direct compliance measure with NFPA 20 (2019 Edition, Section 7.5.1.6*), which mandates the use of a listed torsional coupling for vertical turbine fire pumps driven through right-angle gear drives.

This torsional coupling:

– Absorbs harmful vibration

– Reduces stress on the driveshaft

– Prevents torsional resonance in the operating speed range

– Enhances overall stability and reliability

This innovation ensures longer system life and smooth, trouble-free operation demonstrating NMFIRE’s engineering leadership and strict adherence to international standards.

Structural Design: Column Pipes, Baseplates & Vibration Control

NMFIRE’s vertical turbine fire pumps feature flanged column pipes instead of threaded connections. This design guarantees superior alignment throughout the column assembly, reducing vibration and improving pump efficiency.

Each pump also incorporates a one-piece baseplate with integrated leveling adjustment bolts, simplifying installation and ensuring perfect alignment after setup. These features minimize installation errors and maintain long-term mechanical stability.

In addition, NMFIRE’s vibration control technology ensures the entire pump assembly runs smoothly reducing noise, wear, and maintenance frequency.

Packing Gland & Maintenance Innovation

To minimize water loss and maintenance downtime, NMFIRE has designed a decompression chamber ahead of the soft packing area. This chamber reduces packing flushing water loss, improving sealing performance and extending packing life.

The split-type packing gland design allows for quick and easy replacement without major disassembly, saving both time and labor ideal for facilities requiring minimal downtime

Compliance and Certification

All NMFIRE vertical turbine fire pumps are **UL Listed and FM Approved**, ensuring that every component meets global safety and performance standards. Pumps are designed with a maximum shaft speed limited to **1800 RPM**, as outlined by **NFPA 20**, ensuring safety and durability under continuous operation.

NMFIRE’s compliance ensures that consultants, contractors, and system integrators can confidently specify these pumps in critical fire protection applications, from industrial plants to high-rise buildings.

Why Choose NMFIRE Vertical Turbine Pumps from DFS

As the exclusive agent of NMFIRE in Saudi Arabia, DFS provides complete fire pump solutions that meet international and local standards. Through DFS, customers gain access to:

– Genuine NMFIRE UL/FM certified pumps

– Local technical support and after-sales service

– Engineering assistance and NFPA-compliant system design

Together, DFS and NMFIRE deliver performance that’s not only certified but proven.

Conclusion

Precision is the defining element of NMFIRE engineering. From impellers crafted through the lost wax process to shafts tested ultrasonically, from torsional couplings that absorb vibration to corrosion-resistant materials built for the sea every component reflects excellence.

These design decisions ensure NMFIRE vertical turbine fire pumps deliver efficiency, reliability, and compliance unmatched in the fire protection industry.

When you choose NMFIRE, through DFS, you’re not just choosing a fire pump you’re choosing a system engineered to perform when it matters most.

Tags :